Rebuild or reconstruct your asphalt road with the latest value-engineered solution from Soil and Dust Solutions.

Soil and Dust Solutions continues to provide cost-effective and sustainable solutions for the road industry with the addition of the most advanced method of asphalt recycling.

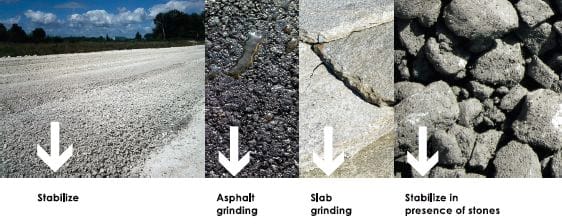

Asphalt recycling is required when the pavement surface has aged, cracked, or become distressed to the point that traditional road maintenance procedures are no longer feasible or cost-effective. Asphalt recycling is achieved through two different methods depending on the severity of the distress to the road. These methods are referred to as surface preservation often called Cold In-Place Recycling (CIR) or Full Depth Reclamation (FDR).

Cold In-Place Recycling (CIR) is the method whereby the existing asphalt surface is crushed and sized with the use of a road recycler machine, mixed in-situ, compacted, and then sealed with our EBS Soil Stabilizer to preserve and protect the surface from fatigue and thermal cracking, raveling and pothole formation.

Full Depth Reclamation (FDR) is the method whereby the existing asphalt surface and underlying layers are pulverized while simultaneously mixing the EBS Soil Stabilizer to a predetermined depth utilizing a road recycler machine in order to create a stabilized base course which is then compacted and sealed with EBS Soil Stabilizer creating a sufficient wearing course. Once complete if required new asphalt may be applied over the wearing course.

For further information about EBS Soil Stabilizer please click here: EBS Soil Stabilizer

The ability to improve and recycle in-situ pavement materials through the implementation of an effective asphalt recycling method provides not only significant savings in both time and cost but also a substantial reduction to the impact on the community and environment during the construction process.

Further benefits of asphalt recycling include:

- Shorter construction time with less disruption

- Eliminates the potential for reflective, fatigue, or thermal cracking

- Provides a homogenously mixed layer with improved structural characteristics

- Eliminates the need for replacement of the existing pavement layer

- Eliminates the need for the importation of additional aggregate material

- Allows for cross slope or profile adjustments for improved drainage

- Reduction in upfront construction costs of 30 to 50%

- Provides significant life cycle cost savings due to reduced maintenance

- Reduced expansion and improved load-bearing strength

- Increased flexibility and high fatigue resistance

Increase the lifespan of your road with Soil and Dust Solutions advanced asphalt recycling methods.

Aspiring to preserve the environment relating to the rising trend of Green Engineering and Construction the following environmental benefits of asphalt recycling are most relevant:

- Reduced energy consumption and greenhouse gas emissions

- Utilization of existing raw materials rather than discarding and replacing

- Eliminates stockpiling or disposal of existing asphalt pavement (increased landfill space)

- Reduced truck traffic as there is no need to import or export materials or aggregate

- Reduced impact on the surrounding community

- Reduced construction time which leads to less dust generation

- Reduced fuel consumption as less construction equipment and trucks are required